Wire Rope Slings ASME B30.9

(1) Minimum 10 times the rope diameter between splices or sleeves.

(2) Horizontal sling angles less than 30 degrees should not be used.

(3) All swaged socket and poured socket assemblies shall be proof tested.

(4) Consult manufacturer if temperatures are below 60 degrees F or above 400 degrees F.

(5) Welded end attachments shall be proof tested.

(6) Eyes shall not be formed using knots.

(7) Wire rope clips shall not be used to fabricate slings.

(8) Remove from service if: abrasion, kinking, crushing, heat damage, broken wires

(10 in one lay or 5 in one strand in one lay), distortion, damaged end attachments,

hooks with 15% spread or 10 degree twist.

(9) Slings shall not be used at load greater than rated capacity.

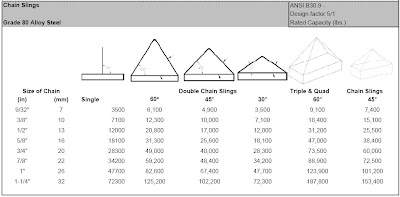

Alloy Steel Chain Slings ASME B30.9

(1) Slings shall not be used at a load greater than rated capacity.

(2) All welded slings shall be proof tested by the sling manufacturer.

(3) Mechanically assembled slings shall be comprised entirely of proof tested components.

(4) Slings shall have permanently affixed identification stating size, grade, rated load and angle on which

the rating is based, reach, number of legs, and sling manufacturer.

(5) Consult mfg. if temperatures are below -40 degrees F or above 600 degrees F.

(6) Attachments or components shall have a rated load equal to the alloy chain.

(7) Slings shall be inspected for damage by a designated person making a record of the conditions, at

least annually.

(8) Repairs shall be made only by the chain mfg. or qualified personnel.

(9) Removal Criteria: missing or illegible sling identification, wear, nicks and gouges, cracked or broken,

bent, weld splatter, heat damage and throat opening or twist in hooks.

Synthetic Web Slings ASME B30.9

(1) Slings shall not be used at a load greater than shown on its tag.

(2) Horizontal angles less than 30 degrees should not be used.

(3) Each sling shall be permanently marked to show: name of the manufacturer, code or stock number,

rated loads for the type of hitches used, any type of synthetic web material.

(4) Reused or welded fittings shall be proof tested 2 times the rated load.

(5) Slings shall be repaired only by a sling manufacturer or qualified person.

(6) Temporary repairs shall not be permitted.

(7) Repaired sling shall be proof tested to two times the rated load.

(8) Periodic inspections should be conducted at least annually, with written inspection records.

(9) Removal Criteria: acid or caustic burns, melting or charring, holes tears, cuts, or snags, broken

or worn stitching, excessive abrasive wear, knots, damaged, cracked or broken fittings.

Utility Rigging Charts

Whenever any sling is used, the following practices shall be observed:

(1) Slings that are damaged or defective shall not be used.

(2) Slings shall not be shortened with knots or bolts or other makeshift devices.

(3) Sling legs shall not be kinked.

(4) Slings shall not be loaded in excess of their rated capacities.

(5) Slings used in a basket hitch shall have the loads balanced to prevent slippage.

(6) Slings shall be securely attached to their loads.

(7) Slings shall be padded or protected from the sharp edges of their loads.

(8) Suspended loads shall be kept clear of all obstructions.

(9) All Employees shall be kept clear of loads about to be lifted and of suspended loads.

(10) Hands and fingers shall not be placed between the sling and its load while the sling is being tightened

around the load

(11) Shock loading is prohibited.

(12) A sling shall not be pulled from under a load when the load is resting on the sling.

(d) Inspections . Each day before being used, the sling and all fastenings and attachments shall be

inspected for damage or defects by a competent person designated by the employer.

Additional inspections shall be performed during sling use, where service conditions warrant. Damaged

or defective slings shall be immediately removed from service.

0 comments:

Post a Comment